Team Training

-

New employee training

New staff must attend 4-week training. This is to make sure they are familiar with Xin-Hong's working procedure and different tool operating, and also corporate philosophy and culture.

-

Pre-operation education

The supervisors must run the pre training before each task to make sure operation runs smoothly and workers are secured.

-

Regular seminars

Include: New engineering technique research, Knowledge of vehicle and machinery maintenance, Client case study, Engineering project case study, Mock practice.

-

On-site supervision

On-the-spot executive must pay attention on each operation, and monitor and teach the staff the correct and safe operating process.

-

Occupational safety and health course

Each of the managers in our company must join the course of "Occupational Safety and Health Manager Training: Type A" held by R.O.C. Association of Occupational Safety and Health.

Safety Manifesto

Engineering criterion, Operation standard • Safety and health, Whole staff participation

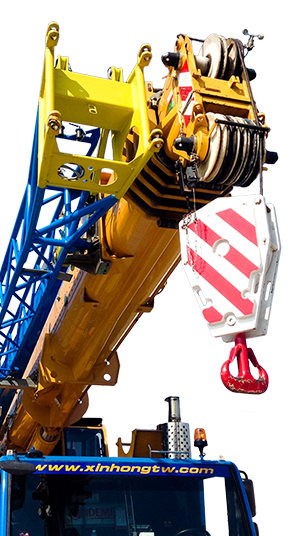

Xin-Hong always focuses on "Staff safety", "Goods safety" and "Equipment safety". To achieve these beliefs, Xin-Hong sets up SOP and asks their staff to follow the procedure for safety reasons.

Xin-Hong Crane Engineering Co., Ltd. has a company core value of "safety first, improvement sustained". Based on safe working environment and safety concept, we provide the best and the safest service quality by continuous improvement and progress.

Pre-operation Preparation

Project manager must strengthen the importance of safety before the operation, and then on-site supervisors assign tasks and allocate team members. Each team runs self-checking before the engineering operation. When the task is proceeding, the safe clearance is need in the surrounding areas. Use traffic cones to distinguish the dangerous to prevent any un-relevant personnel and traffic entering by mistakes.

Operation Safety

- Self-checking before engineering operation.

- Task assignment before operation and safety guidance.

- Operating staff should wear safety helmet, safety shoes, and safety vest.

Transportation Safety

- A transportation route needs to be planned in advance, and double check the condition of the vehicle making sure it is in the ideal status.

- All goods must be fixed tightly in the car.

- Drivers' line of sight should not be obstructed by goods, especially when forklift truck is used. If drivers' line of sight is obstructed by goods, they must drive the forklift truck backwards.

- Vehicle drivers must follow the traffic rules, keep good driving manner, and drive in safe speed.

Work Safety Notice Board

Collecting engineering related working accidents both in Taiwan and from overseas, and post the information here to remind staff must follow the regulations all the time. It is to make sure their own safety, goods safely and the safety of corporate property.

Safety and Health Short-term Training

Manager and all staff must attend the regular "safety and health short-term training", and learn to avoid work accident. The training includes:

- Dangerous machinery and heavy equipment operator training

- Project accident first-aid training

- Dangerous goods operator emergency management training

- Fire-fighting equipment maintenance and fire prevention management

- General safety and health training for all staff

Working Environment Safety

Each project has different engineering layout, and it is very important to plan in details before operation and to observe carefully during the operation. However, accidents sometimes happen; to prevent it causes damage, all the staff on-site must work warily and follow the instruction. Including:

- Supervisors and managers monitor each procedure all the time.

- Each team pays attention to details and reminds other teams for any possible danger during the operation.

- New staff is not allowed to operate independently; one experienced staff must guide and work with him together.

- Rather slow than mistake. Discuss with supervisor if there is any doubt; confirm it before proceeding.

- Make sure all the machine and tools are put back to where they are after the project completed.